Buffoli transbar 13

Buffoli transbar 13

Buffoli Transbar 13

1-Bar feed unit max. stroke 140mm CNC programmable.

Max bar dimension 40mm.

Special bar feed cycle to push out the remnant before feeding a new bar.

CNC controlled adjustable feed out length and bar head length.

1- The finished part is picked up by a two jaw transfer mechanism and dropped

into the exit chute.

10-Self-centering, hydraulic, two jaw, quick change insert jaw chucks.

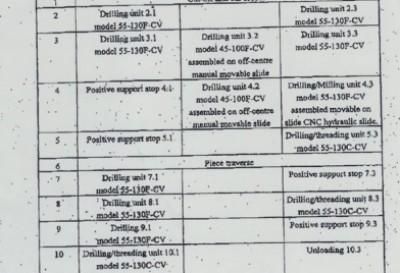

13-Working spindles.

1-CNC milling slide (station 4.3)

1-Electrical cabinet with PLC and CNC control.

1-Automatic bundle bar loader for 4m bar length.

The bar loader will accept 2. 5 tons of bar stock and is programmed to

lift a bar onto the roller way for automatic loading.

1-Coolant filtering and chip conveyor system:

Chip conveyor drag chain model with wide chain

Dirty coolant tank capacity approx.700 lt.

Clean coolant tank capacity approx. 900lt.

Electric motor and pumps

Filter cartridges

Complete electronic and mechanical interface

1-Buffoli tool monitoring system that allows programming the torque

and thrust limits for each unit independently as well as tool wear.

1-Monitor Vishelp system

1-Lot of tool heads for work spindles

1-External mechanical recessing head w/ (2) L cycle mechanical recess

Control, computer programmable

1-Single slide hydraulic recessing head w/(1)CNC hydraulic recess control,

computer programmable

1-Single slide CNC recessing head w/(1)CNC ball-screw recess control,

computer programmable

1-Double slide CNC recessing head (Note it needs a control to operate it)

1-Threading die head “-10 Acme single thread

1-lot misc. Tools, Holders, and (jaws for chuck and feeder)

Condition – like new, low hours and well maintained

Complete with all tooling and attachments shipped with the machine